Exploring the Production Processes and Innovations in Steel Mesh Manufacturing Facilities Worldwide

The Role of Steel Mesh Factories in Modern Construction

Steel mesh, an essential component in the construction industry, plays a critical role in providing strength and stability to structures. It consists of a series of steel wires that are arranged in a grid-like pattern and welded or woven together to create a robust mesh. The production of steel mesh takes place in specialized factories designed to meet the rigorous demands of the construction sector. This article explores the operations, significance, and advancements of steel mesh factories.

Operations of Steel Mesh Factories

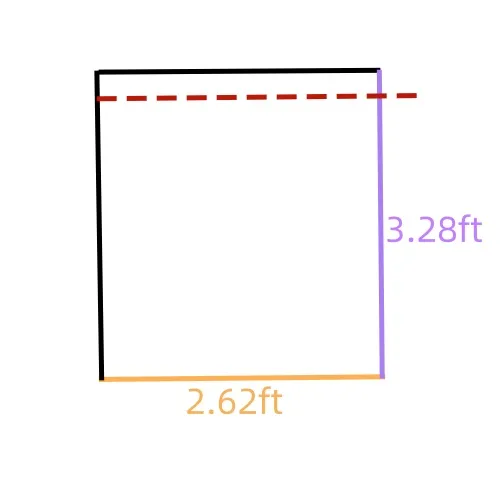

Steel mesh factories utilize advanced machinery and technology to process raw steel into high-quality mesh products. The production process begins with the selection of raw materials, typically high-strength steel wires. These wires are drawn to the desired diameter, ensuring uniformity and strength. Once the wires are prepared, they undergo various processes, including cutting, bending, and welding, to form the mesh.

The manufacturing process often includes automated machinery that increases efficiency and minimization of errors. Operators monitor the machines to guarantee the consistency of the product, which is crucial for safety in construction applications. Following the production, the steel mesh is subjected to rigorous quality control tests. These tests ensure compliance with industry standards and specifications, which vary depending on the intended application, whether for residential, commercial, or industrial construction.

Significance in Construction

Steel mesh serves multiple purposes in construction. One of its primary roles is to reinforce concrete. When concrete is poured, it is inherently strong in compression but weak in tension. Steel mesh adds tensile strength, preventing cracking and improving overall durability. This is particularly important in high-stress environments, such as bridges, highways, and large commercial buildings.

steel mesh factory

Additionally, steel mesh assists in controlling the shrinkage and deformation of concrete. It distributes loads evenly across the structure, thereby enhancing stability and performance. The use of steel mesh is not only limited to concrete reinforcement; it is also utilized in various applications including fencing, roadworks, and even in retaining walls, showcasing its versatility.

Advancements in Steel Mesh Production

With the advancement of technology, steel mesh factories are continually evolving. Innovations in manufacturing processes have led to improved efficiency and sustainability. Today, many factories are incorporating automated systems that minimize manual labor and reduce the risk of human error. These advancements allow for faster production times while maintaining high-quality standards.

Moreover, sustainable practices are becoming increasingly important in the production of steel mesh. Factories are now utilizing recycled steel materials and adopting energy-efficient manufacturing processes, contributing to a greener construction industry. The emphasis on sustainability not only enhances corporate responsibility but also meets the growing demand from clients for environmentally friendly construction practices.

Conclusion

Steel mesh factories are pivotal to the construction industry, providing essential materials that enhance the safety, durability, and efficiency of structures. As the industry continues to evolve, these factories must adapt to new technologies and sustainable practices to meet the ever-growing demands of modern construction. The collaboration between steel mesh manufacturers, construction companies, and regulatory bodies will be crucial in promoting high standards and innovative solutions in the years to come. In essence, the role of steel mesh and its production will continue to be integral in shaping the future of construction worldwide.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024