1 月 . 31, 2025 04:56

Back to list

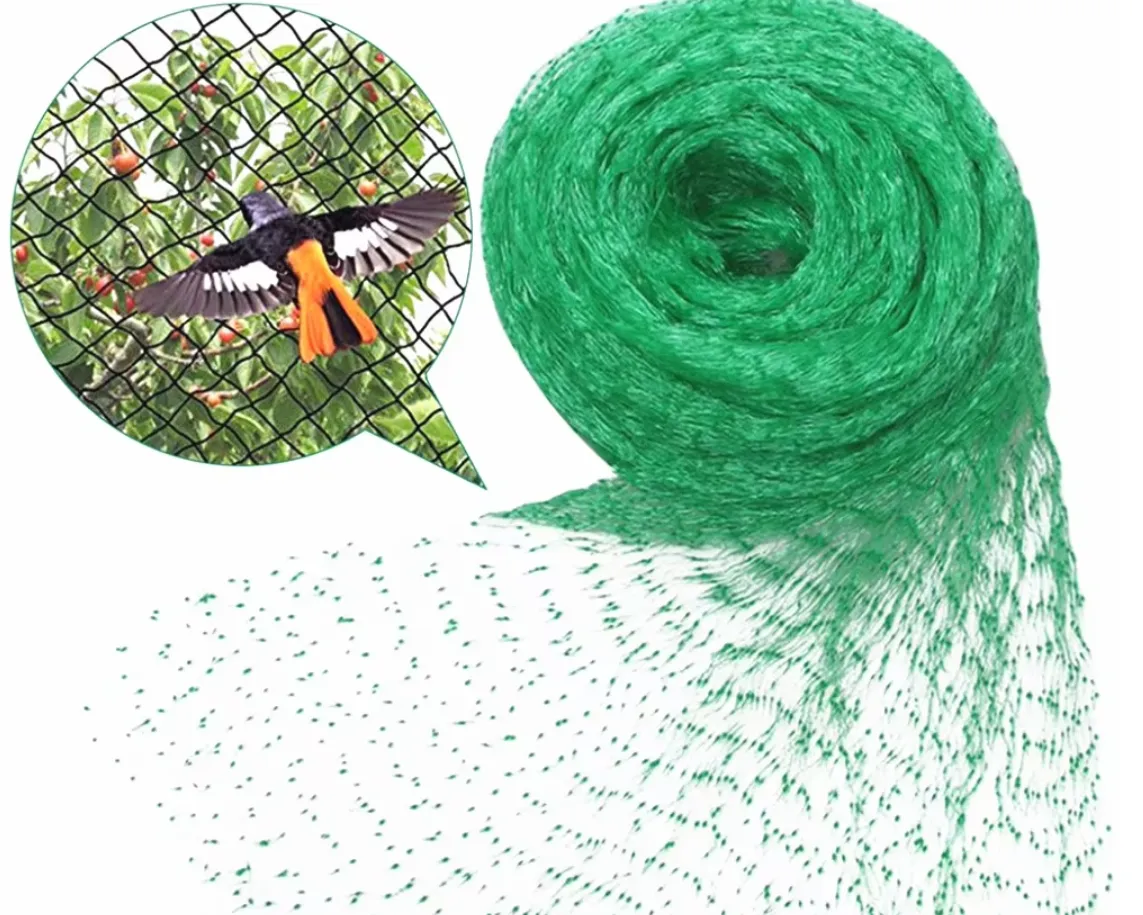

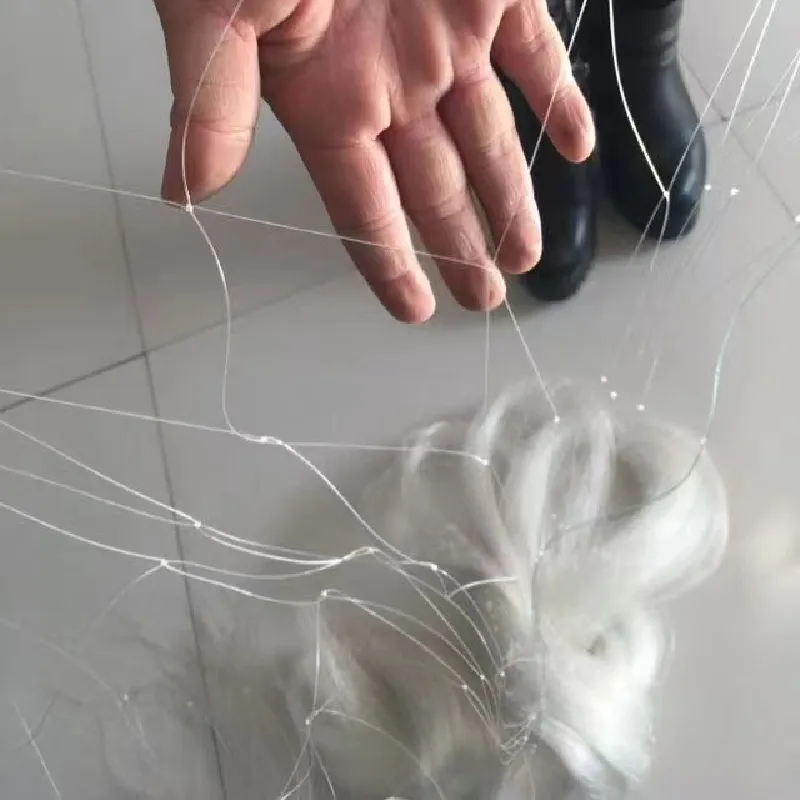

Transparent Net Agro Nets for Vegetable Fruit Tree

The realm of expanded metal fabrication is a fascinating interplay of engineering ingenuity and artistic creativity. This transformative process takes solid sheets of metal and reshapes them into a mesh form, offering a combination of durability, flexibility, and aesthetically pleasing patterns. As industries across the globe continually seek new materials and processes to enhance their products, expanded metal has emerged as a top contender due to its multifaceted benefits.

The fabricator’s expertise and experience are key in realizing the potential of expanded metal projects. Skilled technicians and engineers develop tailored products to meet specific demands, assuring the highest quality and performance. By controlling variables such as strand width, open area, and thickness, fabricators can fine-tune expansion processes to align with specific project requirements. Close collaboration between fabricators and designers ensures that the final product not only meets structural necessities but also excels in aesthetic appeal. Authoritativeness in expanded metal fabrication lies in a fabricator’s ability to consistently deliver quality products that adhere to industry standards. By employing advanced technologies and rigorous testing protocols, leading fabrication companies cement their standing in the field. The strategic selection of metal types – from aluminum and steel to exotic metals like titanium – also underscores their deep understanding of material sciences, thereby reinforcing trust among clients who require precise specifications for specialized applications. Trustworthiness is established through transparent processes, reliability in meeting deliverables, and the provision of comprehensive after-sales support. Building sustained relationships with clients, fabricators ensure not only initial satisfaction but also long-term success by offering refurbishment services, maintenance tips, and ongoing consultation. Such practices build confidence, ensuring that when challenges arise, clients have expert partners to depend upon. In conclusion, expanded metal fabrication is more than a mere production technique; it represents a harmonious blend of engineering prowess, functional design, and aesthetic innovation. As industries evolve and demand more from their materials, expanded metal stands out as a beacon of potential, capable of transforming ideas into tangible reality. Those who engage deeply with this capable material, supported by industry-leading expertise and a commitment to trustworthiness, ensure not only the elevation of their designs but also the enrichment of their creative processes.

The fabricator’s expertise and experience are key in realizing the potential of expanded metal projects. Skilled technicians and engineers develop tailored products to meet specific demands, assuring the highest quality and performance. By controlling variables such as strand width, open area, and thickness, fabricators can fine-tune expansion processes to align with specific project requirements. Close collaboration between fabricators and designers ensures that the final product not only meets structural necessities but also excels in aesthetic appeal. Authoritativeness in expanded metal fabrication lies in a fabricator’s ability to consistently deliver quality products that adhere to industry standards. By employing advanced technologies and rigorous testing protocols, leading fabrication companies cement their standing in the field. The strategic selection of metal types – from aluminum and steel to exotic metals like titanium – also underscores their deep understanding of material sciences, thereby reinforcing trust among clients who require precise specifications for specialized applications. Trustworthiness is established through transparent processes, reliability in meeting deliverables, and the provision of comprehensive after-sales support. Building sustained relationships with clients, fabricators ensure not only initial satisfaction but also long-term success by offering refurbishment services, maintenance tips, and ongoing consultation. Such practices build confidence, ensuring that when challenges arise, clients have expert partners to depend upon. In conclusion, expanded metal fabrication is more than a mere production technique; it represents a harmonious blend of engineering prowess, functional design, and aesthetic innovation. As industries evolve and demand more from their materials, expanded metal stands out as a beacon of potential, capable of transforming ideas into tangible reality. Those who engage deeply with this capable material, supported by industry-leading expertise and a commitment to trustworthiness, ensure not only the elevation of their designs but also the enrichment of their creative processes.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024