2 月 . 14, 2025 09:25

Back to list

empty iv bags

Empty IV bags play a pivotal role in medical and healthcare settings, providing a sterile and reliable means for administering fluids and medications intravenously. As demand for efficient healthcare solutions continues to grow, understanding the nuances of empty IV bags becomes crucial for healthcare professionals aiming for operational excellence and patient safety.

Trustworthiness is further reinforced by the traceability and transparency in the IV bag production process. Reputable manufacturers implement batch tracking and thorough testing documentation to provide full visibility. This transparency reassures healthcare practitioners and patients alike, as it confirms that the products used are both safe and effective. Moreover, advancements in technology have led to the development of eco-friendly IV bags, minimizing environmental impact without compromising on effectiveness. Hospitals striving towards sustainability now have the option of selecting IV bags produced with reduced plastic content or those that are fully recyclable, aligning with broader environmental goals while maintaining clinical efficacy. Choosing the right empty IV bag also involves understanding the various sizes and capacities available, which can be tailored to patient-specific needs. Whether it's a large-volume solution for hydration or a small-dose medication delivery, having the appropriate size ensures optimal fluid management without wastage. Ultimately, the importance of empty IV bags extends beyond their physical presence to embody a commitment to patient safety and quality care. Their design and manufacture reflect continuous innovation and rigorous compliance with health standards, ensuring they remain an indispensable component of modern medical practice. As healthcare continues to evolve, the role of the empty IV bag will undoubtedly adapt, maintaining its position as a cornerstone of intravenous therapy solutions.

Trustworthiness is further reinforced by the traceability and transparency in the IV bag production process. Reputable manufacturers implement batch tracking and thorough testing documentation to provide full visibility. This transparency reassures healthcare practitioners and patients alike, as it confirms that the products used are both safe and effective. Moreover, advancements in technology have led to the development of eco-friendly IV bags, minimizing environmental impact without compromising on effectiveness. Hospitals striving towards sustainability now have the option of selecting IV bags produced with reduced plastic content or those that are fully recyclable, aligning with broader environmental goals while maintaining clinical efficacy. Choosing the right empty IV bag also involves understanding the various sizes and capacities available, which can be tailored to patient-specific needs. Whether it's a large-volume solution for hydration or a small-dose medication delivery, having the appropriate size ensures optimal fluid management without wastage. Ultimately, the importance of empty IV bags extends beyond their physical presence to embody a commitment to patient safety and quality care. Their design and manufacture reflect continuous innovation and rigorous compliance with health standards, ensuring they remain an indispensable component of modern medical practice. As healthcare continues to evolve, the role of the empty IV bag will undoubtedly adapt, maintaining its position as a cornerstone of intravenous therapy solutions.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

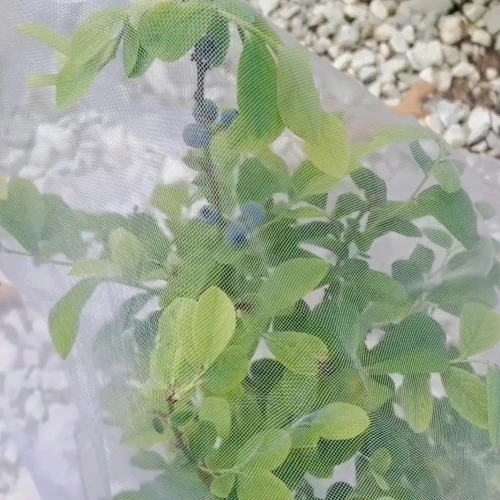

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024