2 月 . 10, 2025 20:59

Back to list

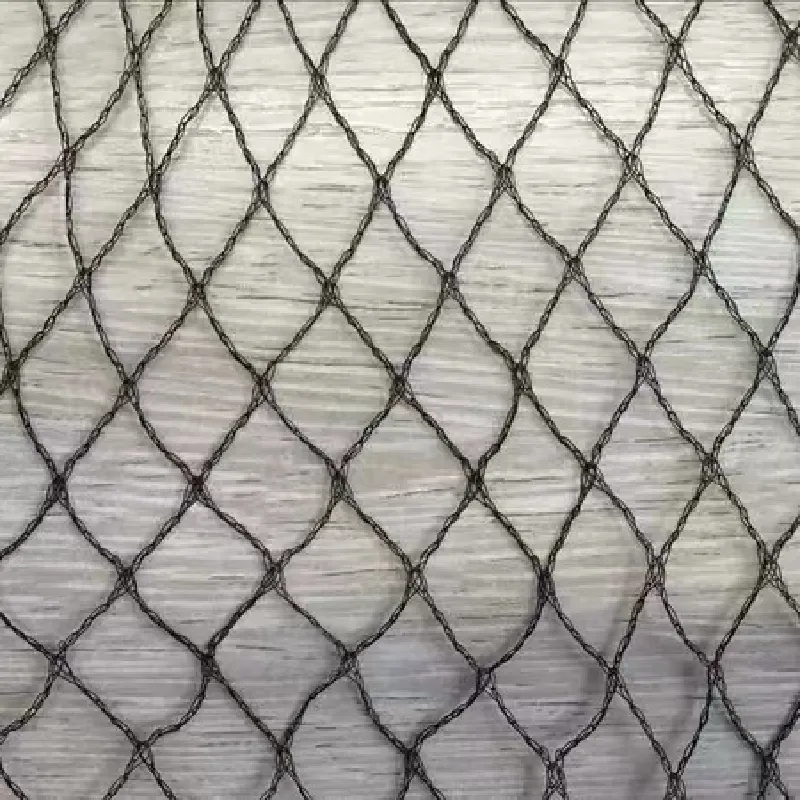

20x20mm Mesh Size Knitted Anti Bird Nets HDPE Agriculture Bird Netting Roll For Birds

Electrowelded mesh, a pivotal element in the construction and manufacturing industries, continues to revolutionize the way infrastructures are built due to its robustness, versatility, and cost-effectiveness. This article delves deep into the nuances of electrowelded mesh, presenting insights rooted in industry expertise and authentic experiences.

Leading authorities in civil engineering emphasize that the electrowelded mesh is not just a product but a crucial technological advancement that supports innovative construction techniques. Its development keeps pace with contemporary demands for sustainable and safe construction materials. By utilizing high-grade materials and advanced technological processes, manufacturers assure stakeholders of the mesh’s reliability and performance over time. Moreover, case studies from real-world applications underscore the material’s efficacy. For instance, in seismic-prone regions, the use of electrowelded mesh has been pivotal in constructing earthquake-resistant structures. Its role in reinforcing concrete results in buildings that can better withstand seismic activities, providing peace of mind to the inhabitants and developers alike. Such stories of success enrich the narrative of electrowelded mesh, echoing its importance in advancing construction safety and innovation. Potential buyers and clients often raise concerns about the environmental implications of using metals. However, electrowelded mesh can be an eco-friendly choice. The material’s durability means it requires less frequent replacement, thus reducing waste. Moreover, many manufacturers are now adopting sustainable practices in their production processes, such as using recycled materials and energy-efficient technologies, to lessen the environmental footprint. In conclusion, electrowelded mesh stands as a testament to engineering expertise and innovation. Its robust properties, ease of installation, and versatility make it an indispensable material in the construction industry. From high-rise buildings to protective roadside barriers, the application spectrum of electrowelded mesh is vast and varied. Its trustworthiness and authoritative presence in the industry are underscored by its track record of successful implementations worldwide. For businesses and projects requiring assured performance and high-quality reinforcement materials, electrowelded mesh represents a forward-thinking choice that aligns with modern engineering standards and environmental considerations.

Leading authorities in civil engineering emphasize that the electrowelded mesh is not just a product but a crucial technological advancement that supports innovative construction techniques. Its development keeps pace with contemporary demands for sustainable and safe construction materials. By utilizing high-grade materials and advanced technological processes, manufacturers assure stakeholders of the mesh’s reliability and performance over time. Moreover, case studies from real-world applications underscore the material’s efficacy. For instance, in seismic-prone regions, the use of electrowelded mesh has been pivotal in constructing earthquake-resistant structures. Its role in reinforcing concrete results in buildings that can better withstand seismic activities, providing peace of mind to the inhabitants and developers alike. Such stories of success enrich the narrative of electrowelded mesh, echoing its importance in advancing construction safety and innovation. Potential buyers and clients often raise concerns about the environmental implications of using metals. However, electrowelded mesh can be an eco-friendly choice. The material’s durability means it requires less frequent replacement, thus reducing waste. Moreover, many manufacturers are now adopting sustainable practices in their production processes, such as using recycled materials and energy-efficient technologies, to lessen the environmental footprint. In conclusion, electrowelded mesh stands as a testament to engineering expertise and innovation. Its robust properties, ease of installation, and versatility make it an indispensable material in the construction industry. From high-rise buildings to protective roadside barriers, the application spectrum of electrowelded mesh is vast and varied. Its trustworthiness and authoritative presence in the industry are underscored by its track record of successful implementations worldwide. For businesses and projects requiring assured performance and high-quality reinforcement materials, electrowelded mesh represents a forward-thinking choice that aligns with modern engineering standards and environmental considerations.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024