3 月 . 06, 2025 11:37

Back to list

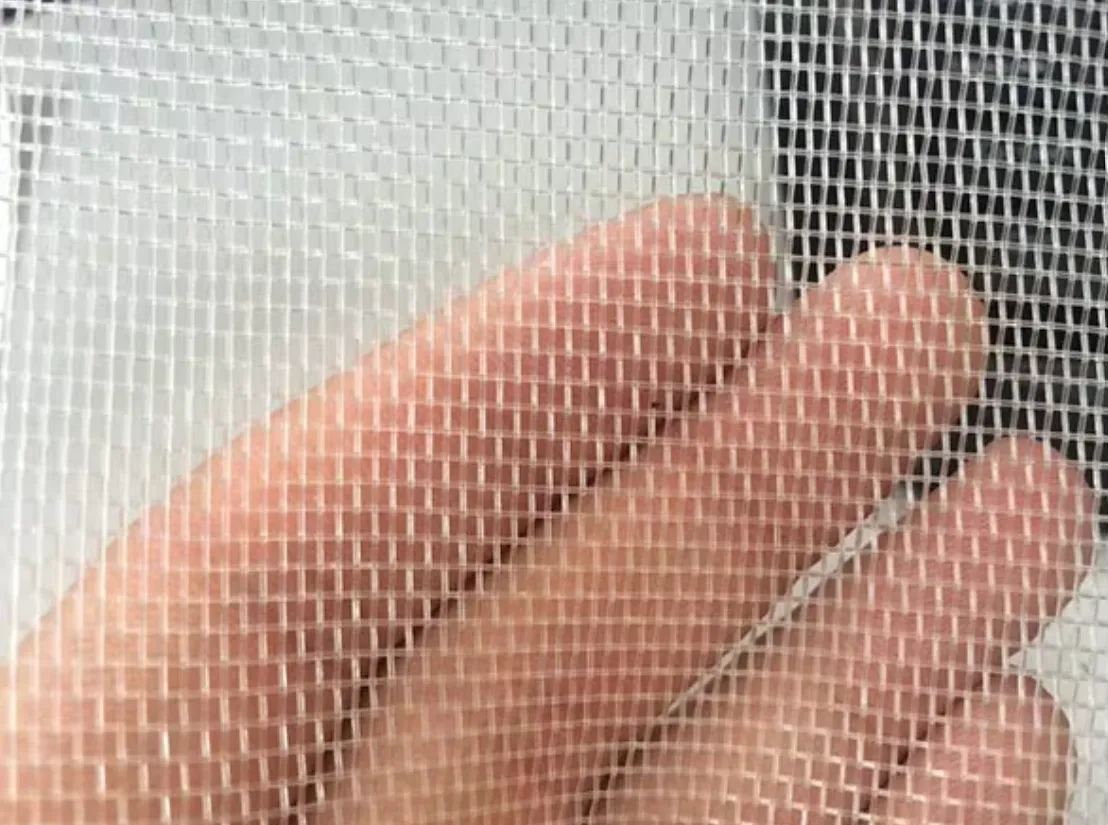

316 stainless steel welded wire mesh

Unmatched resilience and a distinct level of corrosion resistance make the 316 stainless steel welded wire mesh an invaluable asset across various industries. With an impressive pedigree of standing up to the most demanding conditions, this mesh’s benefits go beyond its physical attributes. Drawing from a careful selection of professional insights and hands-on experience, let's delve into why this mesh remains indispensable and how it can be your solution for a range of applications.

Years of empirical evidence support the mesh’s superior quality, offering end-users a reliable reference point for application suitability. Additionally, its aesthetic appeal cannot be overstated. The clean, smooth finish provided by the stainless steel appeals to modern designs, making it suitable for both functional and decorative uses. Whether it's employed in construction for reinforcement or in creative architectural designs for facade embellishments, this material stands to enhance visual and functional appeal simultaneously. Ensuring the authenticity and quality of 316 stainless steel welded wire mesh involves engaging with reputable suppliers who provide verified certifications. These certifications are key indicators of adherence to industry standards, confirming the material’s composition and performance capabilities. Trust in the product is further cemented by proactive after-sales support and guidance, offering clients a sense of security that their specific needs have been thoroughly understood and met with accuracy. To maximize the advantages of the 316 stainless steel welded wire mesh, careful consideration should be given to the specific requirements of the intended application. Consulting with industry professionals and leveraging expert engineering insights can help customize the right mesh solution that aligns with operational demands and environmental conditions. Such decisions not only enhance efficiency but also contribute to a sustainable approach, maximizing the material’s lifecycle and minimizing costs associated with repairs and replacements. In conclusion, the 316 stainless steel welded wire mesh is more than just a robust material; it’s a reflection of meticulous engineering and informed choice. Its repute across various sectors is a testament to its unparalleled performance and reliability. By recognizing its strengths and ensuring high standards in sourcing and implementation, industries can not only prevent operational hurdles but also drive innovation through superior material choices. Thus, opting for 316 stainless steel welded wire mesh is an investment into not just resistant infrastructure but also into future-ready solutions that meet the complex demands of today’s dynamic environments.

Years of empirical evidence support the mesh’s superior quality, offering end-users a reliable reference point for application suitability. Additionally, its aesthetic appeal cannot be overstated. The clean, smooth finish provided by the stainless steel appeals to modern designs, making it suitable for both functional and decorative uses. Whether it's employed in construction for reinforcement or in creative architectural designs for facade embellishments, this material stands to enhance visual and functional appeal simultaneously. Ensuring the authenticity and quality of 316 stainless steel welded wire mesh involves engaging with reputable suppliers who provide verified certifications. These certifications are key indicators of adherence to industry standards, confirming the material’s composition and performance capabilities. Trust in the product is further cemented by proactive after-sales support and guidance, offering clients a sense of security that their specific needs have been thoroughly understood and met with accuracy. To maximize the advantages of the 316 stainless steel welded wire mesh, careful consideration should be given to the specific requirements of the intended application. Consulting with industry professionals and leveraging expert engineering insights can help customize the right mesh solution that aligns with operational demands and environmental conditions. Such decisions not only enhance efficiency but also contribute to a sustainable approach, maximizing the material’s lifecycle and minimizing costs associated with repairs and replacements. In conclusion, the 316 stainless steel welded wire mesh is more than just a robust material; it’s a reflection of meticulous engineering and informed choice. Its repute across various sectors is a testament to its unparalleled performance and reliability. By recognizing its strengths and ensuring high standards in sourcing and implementation, industries can not only prevent operational hurdles but also drive innovation through superior material choices. Thus, opting for 316 stainless steel welded wire mesh is an investment into not just resistant infrastructure but also into future-ready solutions that meet the complex demands of today’s dynamic environments.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024